American scientists invented a 3D printing method using tensegrity structures with shape memory

16 June 17American scientists invented a 3D printing method using tensegrity structures with shape memory

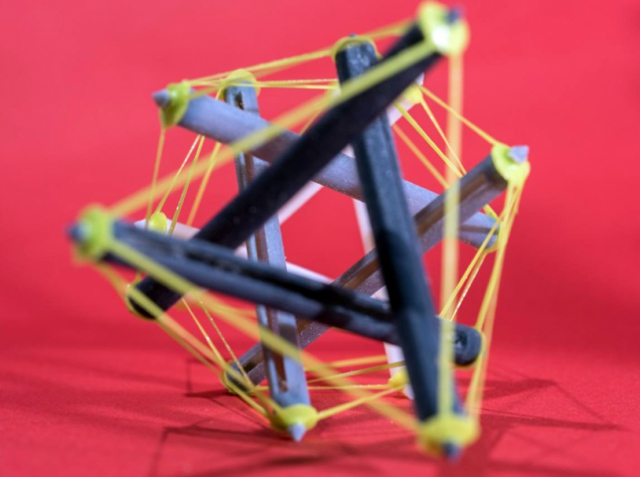

Scientists from the Georgia Institute of Technology have developed a 3D printing method to produce constructions that can flatten and retain the initial shape when heated.

Researchers wanted to create objects based on tensegrity, when constructions are assembled from elements capable to expand and compress. Scientists found out that compressed elements should be printed from materials with shape memory. When heated, the whole object can be partially flattened, transported in such a form, and then heated again to retain the initial shape.

As a test sample, scientists 3D printed supporting struts in the form of hollow tubes with attachment points to connect to 3D printed elastic cables. They heated the object to 65 °С, folded it into W shape, made sure that in a cooled state it preserves almost flat shape, and heated it to the same temperature to make the tubes volumetric again.

According to researchers, tensegrity structures are very lightweight and strong, therefore, can be used to research space. The main goal of the project is to find a way to create large-scale objects that would need little space for transportation, and then after heating would retain their initial shape and fulfil their functions. Thanks to additive technologies, the mission was successfully completed.

Subscribe

Latest News market innovation