Stereolithography: subtleties, advantages, application

18 January 17Stereolithography: subtleties, advantages, application

Additive technologies are gradually becoming an integral part of manufacturing. One of the most widespread 3D printing technologies is stereolithography or SLA printing.

What is stereolithography?

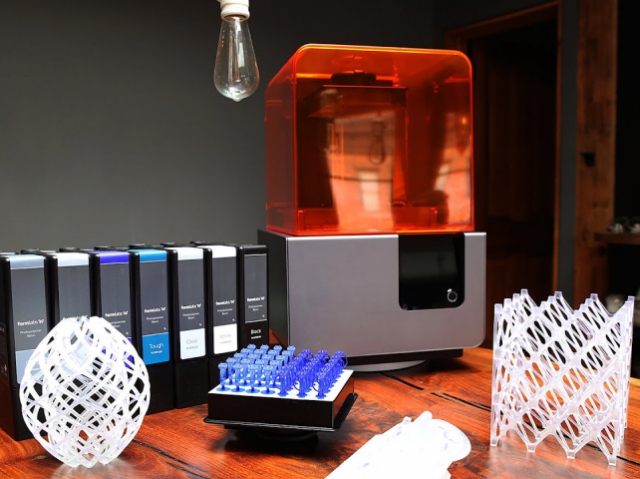

SLA printing is a way of forming a product using a preselected 3D model by applying laser light to liquid resin. In other words, expendable material solidifies under the influence of laser, gaining a specific shape.

Stereolithography was invented over 30 years ago by Charles Hull. The technology was advancing with time and today it is considered to be one of the most popular as it allows obtaining high-quality products with high resolution print – the thickness of layer ranges from 0.03 to 0.1 mm depending on a 3D printer and preset parameters.

Subtleties of SLA technology

Before you send the model to an SLA printer, you have to cut it into separate layers. Special software is used for this purpose. In SLA machines a product is formed on a movable platform. The platform is lowered a distance equal to the thickness of a single layer into the liquid resin, and the laser beam draws the corresponding cut of the 3D model. Printer doesn’t wait till the layer completely solidifies, and continues printing the next layer. When the product is ready, it is rinsed to remove the liquid remains of polymer resin and placed under a UV lamp until it completely hardens. This process takes around 20 minutes.

Such printing technology allows creating extra strong, homogeneous, fine-grained products. And thanks to the fact that the resin solidifies only by 20% before a 3D printer starts forming the next layer, the production time is substantially reduced.

Advantages of stereolithography

Stereolithography has many strong sides:

- allows creating models of complex shape, high resolution and provides excellent reproduction of small elements;

- minimum thickness of a layer is 0.03 mm;

- high printing speed without sacrificing quality;

- readymade product easily lends itself to mechanical treatment and correcting;

- no production wastes;

- maximum sizes of a product created on an SLA printer are 700 × 700 × 700 mm;

- readymade model has excellent mechanical characteristics, is characterized by strength and high quality.

Application areas of stereolithography

Laser stereolithography is used to create engineering and design prototypes, for modeling, building master models, reproduction of objects based on tomography data, etc. It has various application areas: medicine, manufacturing industry, archeology, criminal science, design, art and many others.

SLA technology is not used for mass production of goods yet. It suits more for the creation of single copies of complex models that will serve as robust prototypes. The reason is simple – high price of expendables. One liter of polymer resin can cost from $80 to $120. SLA printers also cost a lot – from $10 000 to $500 000 for a production unit. Although more low-budget models emerge as the technology develops. For example, FORM 1 from Formlabs costs only $2400.

Subscribe

Latest News market innovation