Photopolymers in 3D printing: advantages and application areas

28 December 16Photopolymers in 3D printing: advantages and application areas

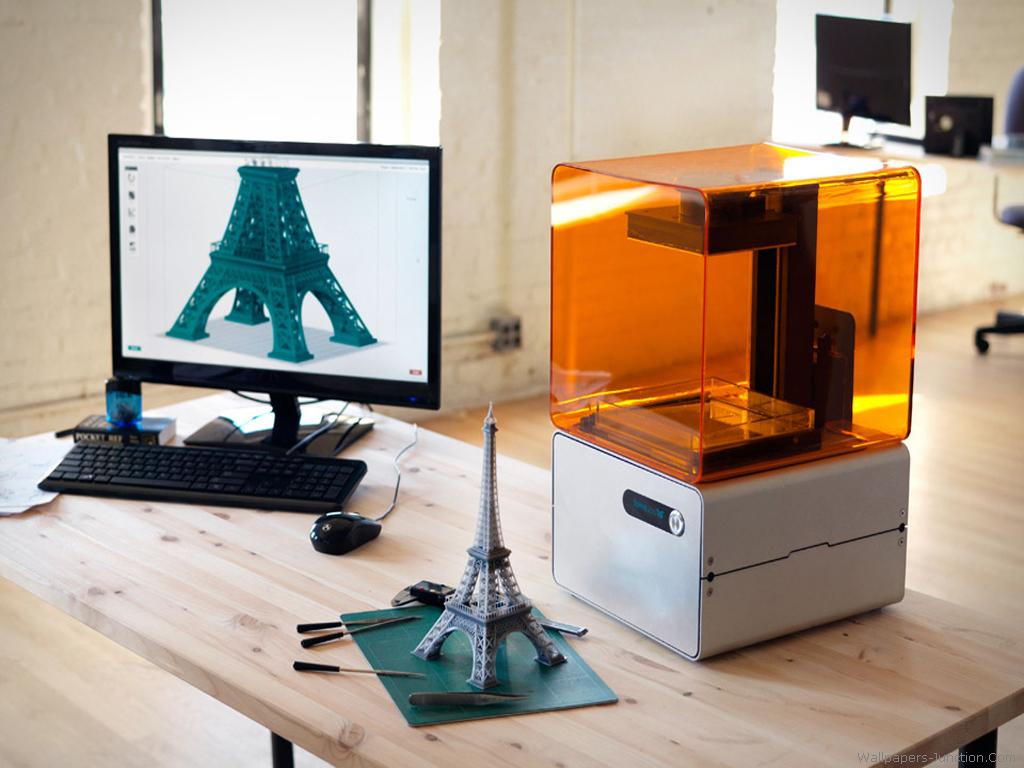

Method of 3D print with photopolymers has become popular for two reasons: it provides high resolution and allows printing the most complex models with various physical properties.

Operating principle of photopolymer 3D printers

This type of 3D printers uses special resins that solidify thanks to the impact of laser, light-emitting diodes or ultraviolet. Correspondingly, there are three kinds of photopolymer 3D printing technologies:

- SLA printing – the most common technology, where a laser is directed at the necessary area of the model, causing the material to solidify layer by layer;

- DLP printing – in this case LED projectors are used to flash and polymerize entire layers, resulting in the faster printing process;

- MJM and PolyJet – the material comes out of many nozzles and solidifies under the influence of ultraviolet. This technology can be used to create models with various physical properties.

Advantages and disadvantages of photopolymer 3D printing

Advantages:

- high resolution of printing when compared to FMD technology;

- end product has a smooth and even surface;

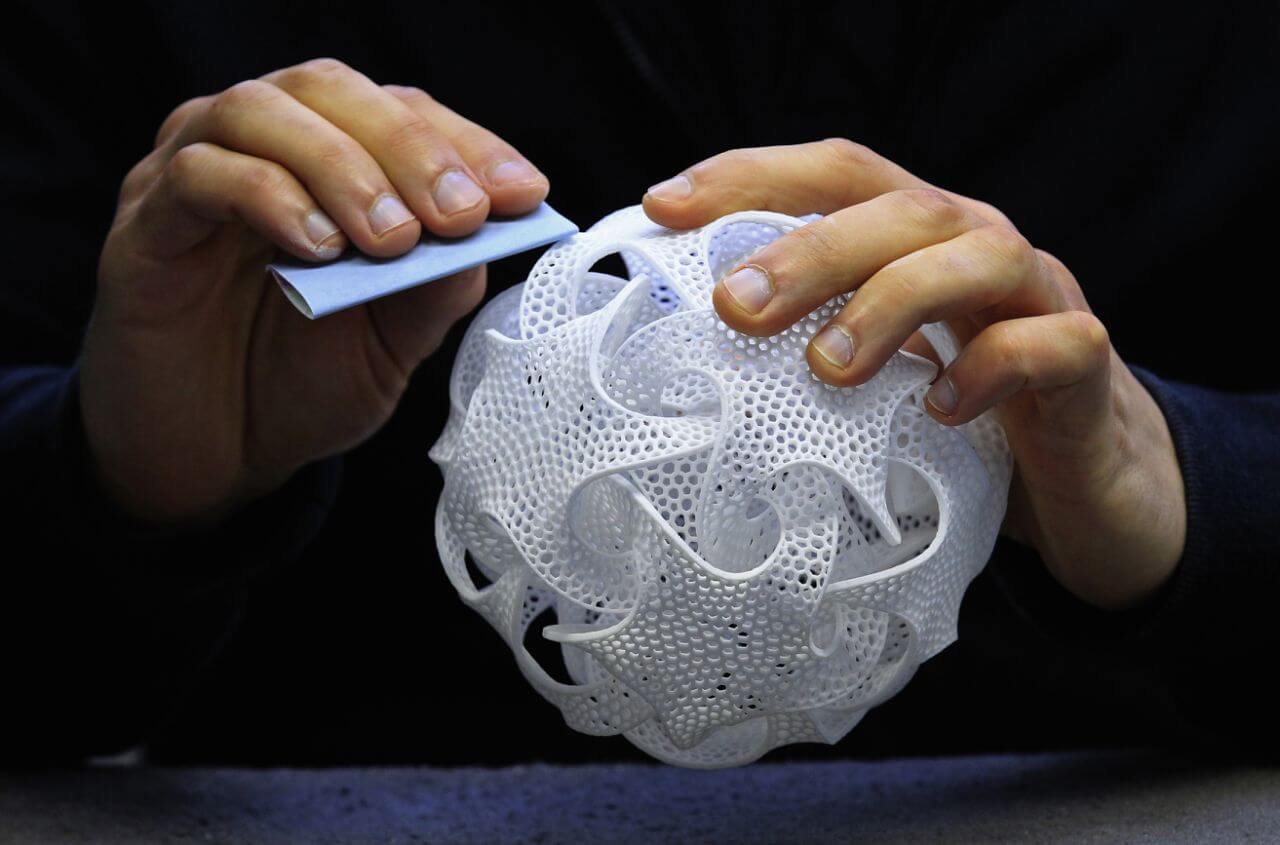

- you can print highly detailed items with complex geometry and different characteristics – the object can be firm or flexible, transparent or opalescent, multicolored or monotonous, etc;

- readymade product is easy to post process – it can be painted, cut, parts can be glued together, etc.

Disadvantages:

- small printing speed, especially when working with SLA printers;

- small assortment of materials;

- some materials are toxic;

- support structures for overhangs are required;

- end products are waterpermeable, you should not use a dishwasher to clean them (meaning that it is better not to print dishes);

- objects can be heated to the temperature of 48 °С, not higher, as they start changing their properties;

- high cost of photopolymer resins.

Despite the long list of disadvantages, photopolymer 3D printing offers many benefits, and has a wide scope of use.

Application areas of photopolymer 3D printing

Photopolymer 3D printing is used in various spheres:

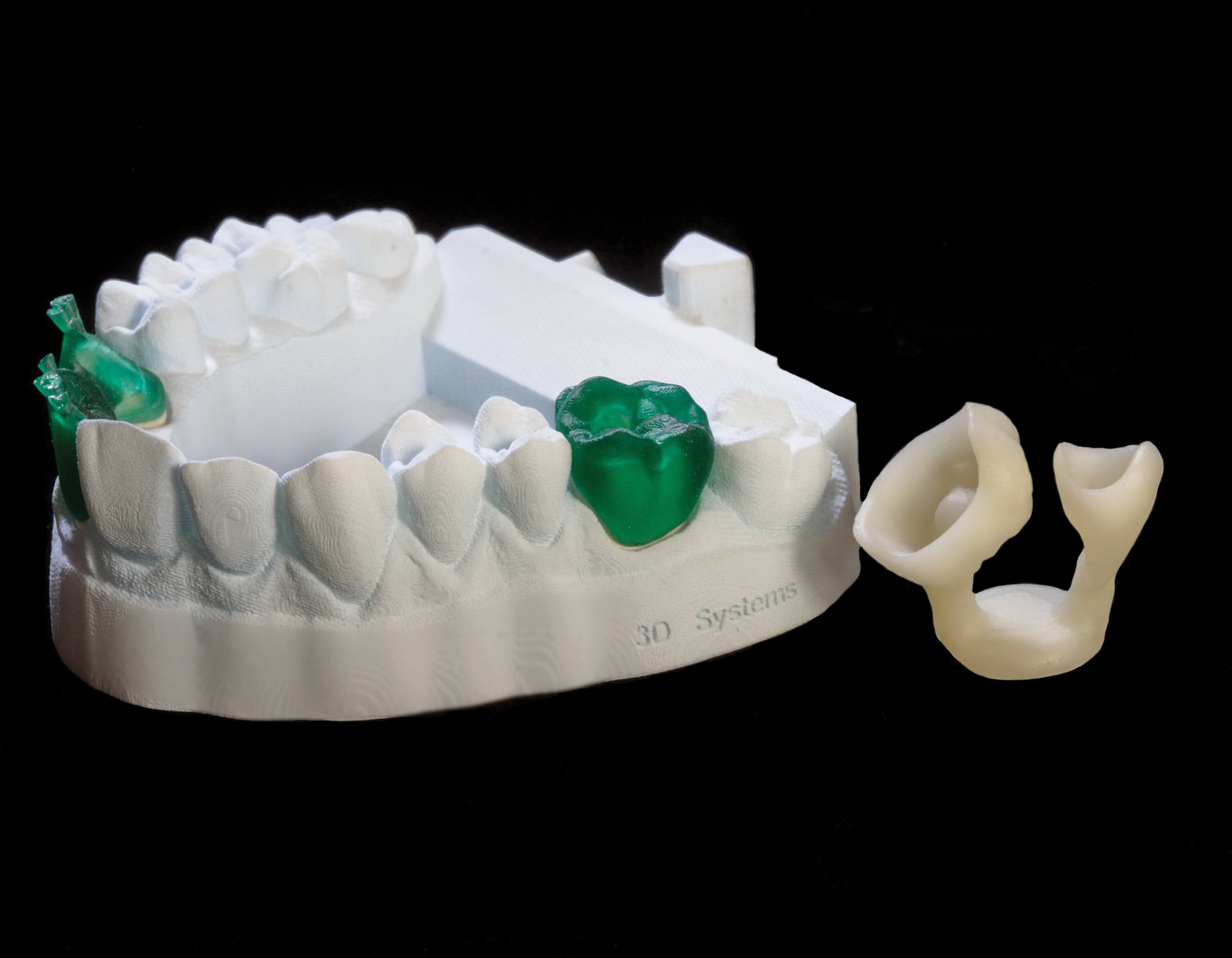

- medicine and stomatology – preparation for surgeries, creation of prostheses and instruments;

- jewellery – production of original jewelry models for further creation of casting molds;

- industry – individual production of different component parts, prototyping, creation of master models, etc.;

Nowadays, photopolymer 3D printing has become one of the basic additive manufacturing technologies and continues to advance.

Subscribe

Latest News market innovation